Testing and Research

Spiegler's Strength of Research

In-House testing at our facility in Dayton, Ohio

All testing is performed according to the Federal Motor Vehicle Safety Standard 106 (FMVSS-106). All of our brake lines pass these rigorous tesing procedures. The 3 most demanding test procedures are listed below.

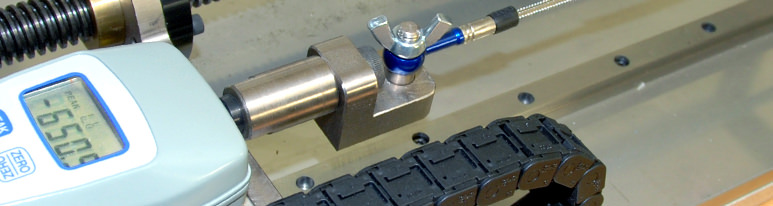

High-Pressure Test - Forces brake fluid into lines and fittings to measure the ability of Spiegler Brake Lines to exceed DOT standards. The FMVSS-106 requires a maximum pressure of 5,000 PSI which our brake lines easily exceed.

Tensile Strength Test - Attempts to pull apart brake lines and fittings to measure the strength of our materials and construction. This test convinced us that we could lift a bike using just one brake line and fitting.

Whip Test - Spins a pressurized brake line and fitting for 35 hours to ensure its ability to withstand years of use on the road or the track.